Captain Shem Malmquist

The following information was adapted from an article on brake use by Capt. Simon, UAL (Ret), and portions have been reprinted with permission. It is intended for informational purposes only and is not intended to supersede your company procedures. As always, the guidance in the in official publications should be adhered to.

Many newer aircraft are equipped with carbon brakes, as opposed to the steel brakes found on relatively older aircraft. Carbon brakes have different characteristics and should be operated differently than steel brakes.

When operating an aircraft equipped with steel brakes, it is best to use full reverse thrust and minimum braking as a way to minimize the heat input into the brake’s heat stack (rotors and stators). This is especially true in a through-flight type operation where the aircraft is not on the ground long enough for the brakes to cool. However, this operating technique can reduce the brake life if used on aircraft equipped with carbon brakes. First, some background:

Carbon brakes have some great advantages over steel brakes:

However, they have some limitations:

(Photo from http://www.boeing.com/commercial/aeromagazine/articles/qtr_03_09/article_05_1.html)

Brake assemblies wear differently depending on material and aircraft. Steel brakes can wear much more quickly than carbon brakes as heat build-up reduces the life of a steel brake. The interior of the wheel gets the hottest as it will not radiate heat as easily. Even when not braking, normal taxi will result in heat build up from friction associated with the tire rotation itself – the latter increasing rapidly as the speed is increased above normal taxi speed. This normal (non-braking) heat is highest at the tire bead and lower sidewall area as this is the area where all the tire forces terminate as well as being the thickest area of the tire. This, coupled with the landing gear loads generated during taxi (particularly during turns), are the reason many large aircraft have published taxi speed limitations.

As the hottest portions of a steel brake wear the fastest, it is not surprising that the pads and linings on the inside of the brake stack and wheel will wear the most quickly. The interior linings are thicker than the outside linings in anticipation of this uneven wear pattern.

Conversely, carbon brakes wear uniformly and actually perform better the hotter they get. However, activating a carbon brake when the assembly is cold wears them dramatically – the carbon brake’s “worst case” is during initial taxi when they are usually at their coldest. Despite that, if operated properly, a carbon brake wears better than a steel brake. For example 1/ 8” of wear on a carbon brake may equate to 200 landings, where the same 1/ 8” for a steel brake may only net 20 landings (depending on aircraft type).

Following is a short summary of some of the differences between carbon and steel brakes:

The following is paraphrased from the BFGoodrich Engineering Report 7437:

Brake wear factors: Steel brake wear is a function of the amount of energy absorbed during aircraft landing. Less energy (lower temperature) nets longer life. Carbon brake wear is a function of the number of times the brakes are applied and the temperature at which they are applied. Longer brake life will result from fewer applications and maintaining higher brake temperatures.

High life carbon brake use is characterized by:

Low life carbon brake use is characterized by:

Recommendations to improve Carbon Brake life – Pilot Technique:

Remember that:

From gate departure to takeoff – traffic conditions permitting, minimize frequency of taxi brake applications:

During landing and rollout – conditions permitting, achieve higher brake-on speeds:

From landing to gate – traffic conditions permitting, minimize frequency of taxi brake applications:

The bottom line is that carbon brake life is most affected by the number of brake applications and how hot the brakes are during those applications. For example, if the target speed is 20 knots consider allowing the speed to build up to 20 knots and then slow it to 5 knots with a continuous braking application once or twice during taxi as opposed to maintaining the speed close to 20 knots with multiple very light brake applications. Similarly on landing, consider letting the carbon brakes heat up by getting on the binders early in the ground roll and then stay on them with continuous application until taxi speed.

This article was intended to increase your brake awareness. Saving the brakes increases the odds that they will be there for you (or someone else) when really needed, however it again must be emphasized that pilots follow the official their official company guidelines. This applies to all operational procedures, not just brake use – if an incident were ever to occur, it is a whole lot simpler to defend yourself if you were doing it the way the company told you!

Here is some more information on the topic.

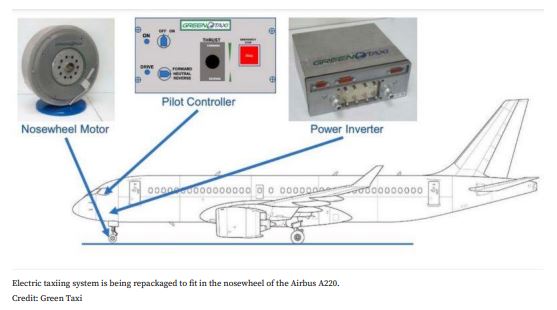

In 2011, a team led by L-3 Communications demonstrated electric taxiing at Frankfurt Airport with a Lufthansa Airbus A320. In…

Read More

Carbon Brakes Captain Shem Malmquist The following information was adapted from an article on brake use by Capt. Simon, UAL…

Read More

14 CFR Part 39 [Docket No. FAA-2022-0160; Project Identifier AD-2022-00009-E] RIN 2120-AA64 Airworthiness Directives; CFM International, S.A. Turbofan Engines (summary)…

Read More

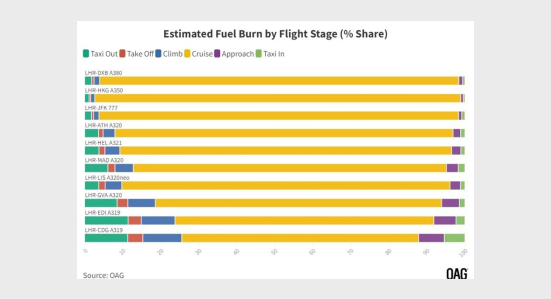

In this analysis, we use the model to take a look at a selection of flights for a specific day…

Read More

On average, a single-aisle jet burns more than 65 gallons of fuel while taxiing, which translates to almost $130 per…

Read More