The Electric Green Taxi System was later also installed on a Lufthansa A-320 and did taxi demonstrations with jet engine covers in place at the Frankfurt airport in 2010 and received a no technical objection from Airbus Delete words “in 2010”…

Capability: : Top speed of 15-25 MPH (depending on configuration and power)

Weight: Approximately 200 lbs. net weigh

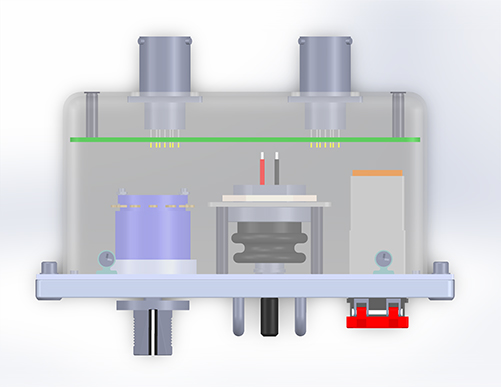

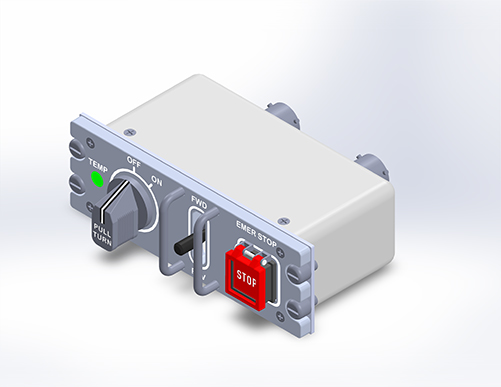

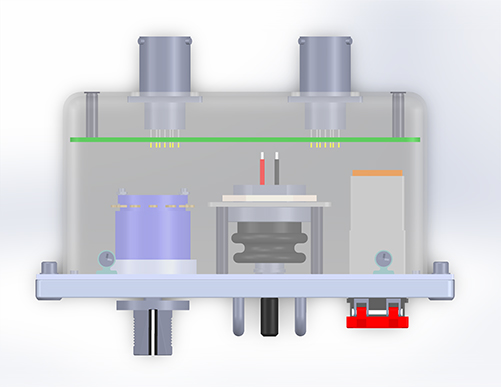

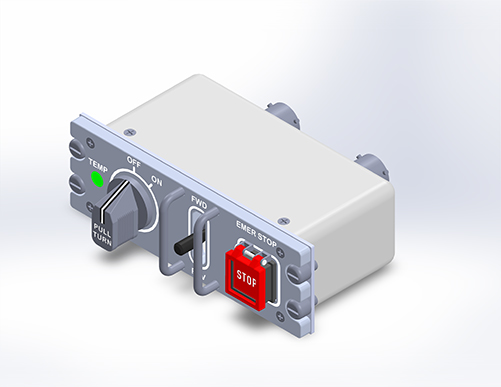

Components: Entirely onboard: In-wheel motors, Inverter, Wire harness, Cockpit interface.

Green Taxi is relatively simple product which is designed for rapid retrofit on existing aircraft. The four parts of the Green Taxi system are:

Green Taxi can be easily installed during aircraft build and retrofitting is possible during nominal C checks. If more time is required then it can be integrated into heavy maintenance D check to be installed concurrently. The DC motors used by Green Taxi are extremely reliable,