Fuel savings

CARBON BRAKE SAVINGS

Assumptions for savings calculations

PUSHBACK SAVINGS

TOTAL DIRECT COST SAVINGS

ENGINE START LATENCY SAVINGS

EMISSIONS SAVINGS

Emissions Control Benefits

Ground operation greenhouse gas emissions (CO2, CO, NOx, HC, SO2 and PM) reduced by 85%.

Less use of the brakes during the taxi phase

Reduced engine maintenance & operating costs

Improved aircraft turnaround times, aircraft utilization, and schedule dependability

Increase safety to ground personnel and equipment

Eliminates the need for tractors/tugs for ground operations.

Increased safety for ground personnel protected from jet blast, jet emissions & noise

Corporate branding and customer goodwill - A Greener Fleet

reduction in jet fuel during taxling

reduction in CO2 & noxious gases

reduction in noise during taxling

reduction in foreign object damage

increase in gate eficiency

The Green Taxi System is a potential alternative means of compliance to the CFM engines proposed AD due to damage from dust as the engines will run 85% less on the ground by utilizing our Electric Taxi Operation instead of having the main engines operating on the ground.

DEPARTMENT OF TRANSPORTATION

Federal Aviation Administration 14 CFR Part 39 [Docket No. FAA-2022-0160; Project Identifier AD-2022-00009-E] RIN 2120-AA64 Airworthiness Directives; CFM International, S.A. Turbofan Engines (summary)

AGENCY:Federal Aviation Administration (FAA), DOT.

ACTION:Notice of proposed rulemaking (NPRM).

SUMMARY:The FAA proposes to adopt a new airworthiness directive (AD) for certain

CFM International, S.A. (CFM) LEAP-1A model turbofan engines. This proposed AD was prompted by reports of two in-flight shutdowns (IFSDs) and subsequent investigation by the manufacturer that revealed cracks in the high-pressure turbine (HPT) rotor stage 1 blades (rotor stage 1 blade deterioration and airfoil distress due to the build-up of dust.). The FAA is proposing this AD to address the unsafe condition on these products.Background The FAA received reports of two single-engine IFSDs on airplanes powered by LEAP-1A model turbofan engines, operating extensively in the Middle East and North Africa (MENA) region. A post-flight BSI of the HPT module revealed that the engine failures were due to cracks in the HPT rotor stage 1 blades. After investigation, the manufacturer determined that engines operating in the MENA region are susceptible to accelerated HPT rotor stage 1 blade deterioration and airfoil distress due to the build-up of dust. This unsafe condition, if not addressed, could result in failure of the engine, in- flight shutdown, loss of thrust control, and loss of the airplane. The FAA estimates the following costs to do any necessary reporting and replacements that would be required based on the results of the proposed inspections. The agency has no way of determining the number of airplanes that might need these replacements.

Action Labor Cost Parts Cost Cost per product Replace the HPT rotor stage 1 blades 150 work-hours x $85 per hour = $12,750 Labor Plus $988,200 $1,000,950 in Damaged Parts Cost Replace the HPT stator stage 1 nozzle set 24 work-hours x $85 per hour = $2,040 Labor Plus $701,460 $703,500 in Damaged Parts Cost

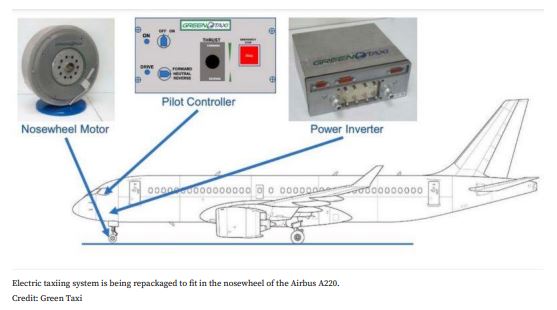

In 2011, a team led by L-3 Communications demonstrated electric taxiing at Frankfurt Airport with a Lufthansa Airbus A320. In…

Read More

Carbon Brakes Captain Shem Malmquist The following information was adapted from an article on brake use by Capt. Simon, UAL…

Read More

14 CFR Part 39 [Docket No. FAA-2022-0160; Project Identifier AD-2022-00009-E] RIN 2120-AA64 Airworthiness Directives; CFM International, S.A. Turbofan Engines (summary)…

Read More

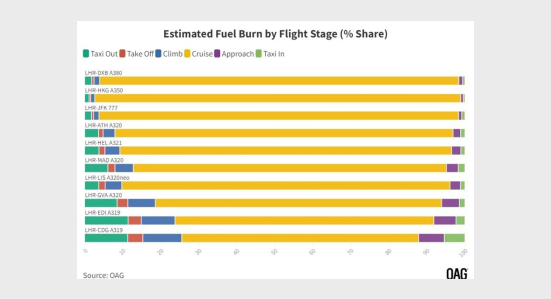

In this analysis, we use the model to take a look at a selection of flights for a specific day…

Read More

On average, a single-aisle jet burns more than 65 gallons of fuel while taxiing, which translates to almost $130 per…

Read More